HDPE LASER MARKING

ABMARK laser equipment is used to encode and mark products of a wide variety of materials, including paper, cardboard, plastics (PET, PVC, HDPE), glass, metals and wood. The messages and graphics that are achieved are of high quality, at a minimum operating cost and at high speeds.

Application News regularly provides a sample of products that are encoded and labelled with ABMARK lasers, every day and worldwide.

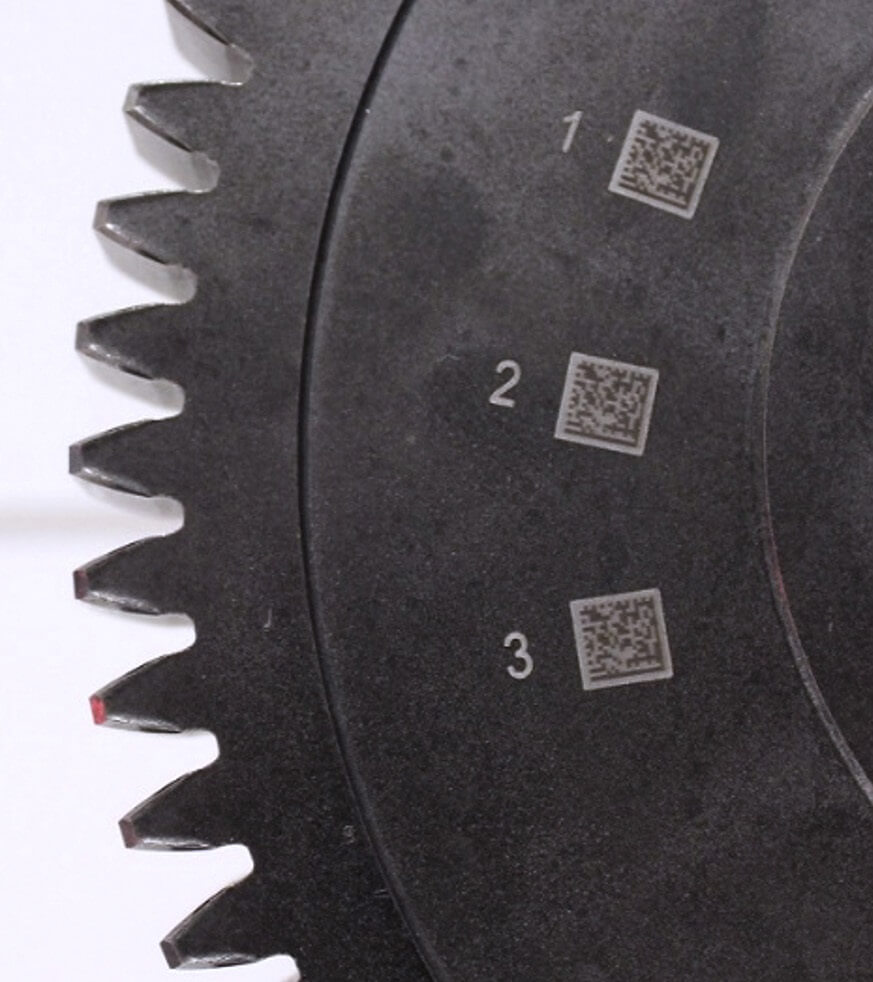

Laser marking technology in the automotive sector is perfect for different types of materials and surfaces, such as plastic or metal, ensuring characters, logos and codes that stand out for their efficiency and legibility, as well as being fine, precise and indelible.

In this Application News, two types of steel laser marking have been carried out.

|

On the one hand, a first marking of a datamatrix code which is perfectly readable and has good contrast. The datamatrix code can contain fixed and variable fields for perfect traceability of production lines, operators, dates, batch codes, serialization, and so on.

On the other hand, the second marking is a human readable marking where the residual steel is cleaned to obtain a white marking, which makes it more visible, in a circular shape that adapts to the shape of the part. It should be emphasized that the datamatrix and text marking time is only 2.0 seconds. All this is made possible thanks to the AB-F Series. |

| LASER: | AB-F SERIES |

| LENS: | 100X100MM |

| MARKET: | AUTOMOTIVE |

| APPLICATION TYPE: | MARKING |

| PRODUCT: | GEARS |

| MATERIAL: | STEEL |

| MARKING TYPE: | STATIC |

| MARKING TIME: | 2.0 seconds |